Why Understanding the Custom Home Builder Process Matters

The custom home builder process can feel overwhelming, but it doesn’t have to be. When you know what to expect, you can make smart decisions and avoid costly mistakes that derail your timeline and budget.

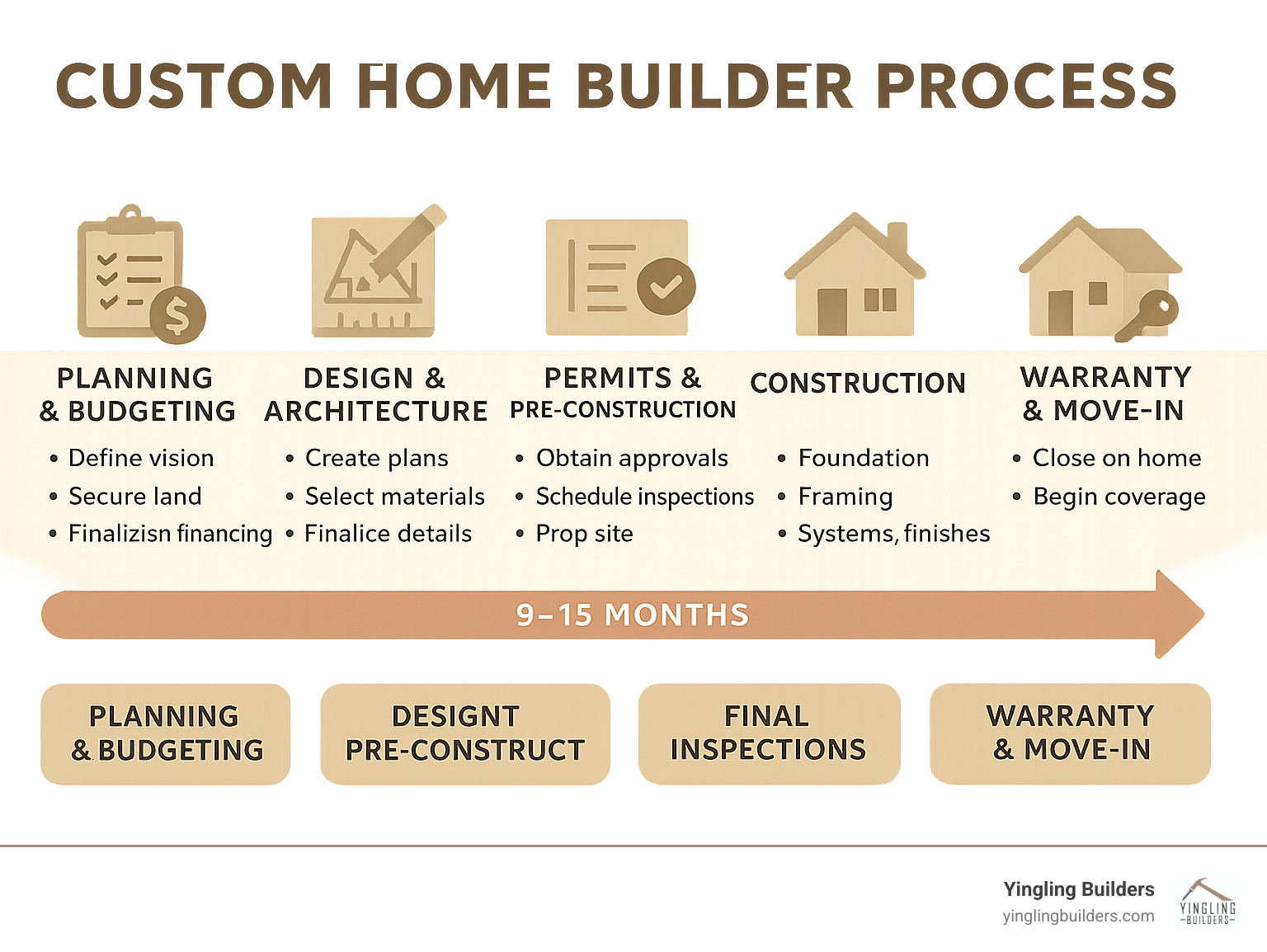

The custom home builder process follows 6 core phases:

- Planning & Budgeting – Define your vision, secure land, and establish realistic financing

- Design & Architecture – Create detailed plans, select materials, and finalize structural elements

- Permits & Pre-Construction – Obtain approvals, schedule inspections, and prep the site

- Construction – Build through foundation, framing, systems, and finishing phases

- Final Inspections – Complete walk-throughs, address punch list items, and receive approvals

- Warranty & Move-In – Close on your home and begin your warranty coverage period

The entire process typically takes 9-15 months depending on your home’s complexity, local permitting timelines, and material availability. Weather, labor shortages, and change orders can extend this timeline.

Most homeowners feel stressed because they don’t understand when decisions need to be made or what comes next. But with the right roadmap, you can steer each phase confidently while staying on budget and schedule.

I’m Seth Yingling, owner of Yingling Builders with over 15 years of hands-on construction experience. I’ve guided dozens of families through the custom home builder process, helping them avoid common pitfalls while building their dream homes throughout West Central Illinois.

Understanding the Custom Home Builder Process Roadmap

Think of the custom home builder process as a journey with specific stops along the way. Each phase builds on the previous one, so understanding the entire roadmap helps you prepare for what’s coming next.

The beauty of having a clear roadmap is that you can frontload decisions during the planning phase, which prevents costly delays later. Research shows that homeowners who understand the process from the start experience 40% fewer change orders and finish an average of 6 weeks ahead of schedule.

The 6 Core Phases of the Custom Home Builder Process

Phase 1: Planning & Budgeting (1-2 months)

This is where we define your vision, evaluate potential lots, and establish realistic financing. You’ll create a wish list of features, determine your must-haves versus nice-to-haves, and secure your construction loan approval.

Phase 2: Design & Architecture (2-4 months)

We’ll work with architects to create detailed plans, select structural materials, and finalize your home’s layout. This includes everything from room sizes to window placement and exterior finishes.

Phase 3: Permits & Pre-Construction (1-2 months)

We handle permit applications, schedule required inspections, and prepare your building site. This phase includes soil testing, utility connections, and final plan approvals.

Phase 4: Construction (4-8 months)

The actual building begins with site preparation and foundation work, progressing through framing, mechanical systems, and interior finishes. This is the longest phase and where most of your time and attention will be focused.

Phase 5: Final Inspections (2-3 weeks)

We conduct multiple walk-throughs, address any punch list items, and complete final inspections. This ensures everything meets building codes and your quality standards.

Phase 6: Warranty & Move-In (Ongoing)

You’ll receive your keys, close on the home, and begin your warranty period. Most builders offer 1-year workmanship warranties, 2-year mechanical system coverage, and 10-year structural warranties.

Typical 9-15 Month Timeline—What Really Drives It?

According to the U.S. Census Bureau, the average custom home takes longer than the standard 7-month timeline for production homes. Here’s what actually drives your timeline:

Weather Impact (2-6 weeks of delays)

Rain, snow, and extreme temperatures can halt construction, especially during foundation and roofing phases. In West Central Illinois, we typically see weather delays between November and March.

Labor Availability (1-4 weeks)

Skilled tradespeople are in high demand. Scheduling conflicts with electricians, plumbers, and specialty contractors can create bottlenecks, particularly during peak building season.

Material Lead Times (2-8 weeks)

Custom windows, specialty appliances, and unique finishes often have extended lead times. Supply chain disruptions can extend these delays further.

Permitting Timelines (2-6 weeks)

Municipal approval processes vary significantly. Some jurisdictions review permits within 2 weeks, while others take 6-8 weeks for complex custom homes.

Design Complexity (1-3 months)

Homes with unique architectural features, complex mechanical systems, or extensive customization require more design time and often additional engineering review.

Planning & Budgeting Without the Headaches

The planning phase sets the foundation for your entire project. Get this right, and the rest of the custom home builder process flows smoothly. Rush through it, and you’ll face expensive surprises later.

Choosing & Vetting the Right Lot or Land

Your lot choice affects everything from your home’s orientation to your final budget. Here’s what we evaluate with every client:

Topography and Drainage

Sloped lots require additional grading and may need retaining walls. Poor drainage can add thousands to your foundation costs. We always recommend a professional survey and soil test before purchasing.

Solar Orientation for Energy Efficiency

Positioning your home to maximize natural light and minimize energy costs is crucial. South-facing windows capture winter sun, while proper roof orientation optimizes solar panel placement if you choose to install them.

Setback Requirements and Building Restrictions

Every lot has setback requirements that determine where you can build. HOA restrictions may limit your home’s size, style, or exterior materials. We review these constraints before finalizing your design.

Infrastructure and Utility Access

Lots without existing utilities can add significant costs. Installing septic systems, wells, or extending electrical service can easily add $15,000-$40,000 to your budget.

Teardown vs Raw Land Considerations

If you’re buying a lot with an existing structure, factor in demolition costs and disposal fees. However, existing utilities and established landscaping can offset these expenses.

Building a Bullet-Proof Budget & Financing Plan

A realistic budget prevents the stress of mid-construction financial surprises. We break down costs into three categories:

Hard Costs (75-80% of budget)

These include materials, labor, and direct construction expenses. Hard costs are relatively predictable once your plans are finalized.

Soft Costs (15-20% of budget)

Permits, inspections, architectural fees, and temporary utilities fall into this category. These vary by location and project complexity.

Contingency Fund (5-10% of budget)

Unexpected issues like poor soil conditions or change orders require additional funds. We recommend maintaining a 10% contingency for first-time builders.

Construction Loan Mechanics

Construction loans differ from traditional mortgages. You’ll pay interest only during construction, with funds released in draws as work progresses. Most lenders require 20-25% down and detailed construction plans before approval.

Draw Schedule Management

Typical draw schedules include: foundation completion, framing, dried-in (roof and exterior), mechanicals rough-in, drywall completion, and final completion. Understanding this schedule helps you manage cash flow.

Matching Builder Type to Your Goals

| Builder Type | Customization Level | Timeline | Cost Control | Best For |

|---|---|---|---|---|

| Production Builder | Low – preset plans with limited options | 4-6 months | Highest – fixed pricing | Budget-conscious buyers wanting quick delivery |

| Semi-Custom Builder | Medium – modify existing plans | 6-9 months | Moderate – some flexibility | Buyers wanting some personalization without full custom complexity |

| Custom Builder | High – fully customized design | 9-15 months | Variable – depends on choices | Buyers with specific vision and flexible timeline |

We specialize in the semi-custom approach, using Wausau Homes’ proven plans as a starting point while allowing significant customization. This gives you design flexibility while maintaining cost predictability and construction efficiency.

Design & Selections Like a Pro

The design phase is where your vision becomes reality. It’s also where poor planning can lead to expensive changes later in the custom home builder process.

More info about design | Houseplans resource

Collaborating With Architects & Interior Designers Early

Schematic Design Phase

We start with bubble diagrams and basic layouts to establish room relationships and traffic flow. This is the time to make major layout changes without affecting your budget.

Mood Boards and Style Direction

Creating visual references for your desired aesthetic helps ensure everyone’s on the same page. We encourage clients to collect inspiration photos and material samples early in the process.

Value Engineering Opportunities

Experienced designers can suggest cost-effective alternatives that achieve your desired look. For example, using engineered lumber instead of solid wood for structural elements can reduce costs while maintaining performance.

Structural Changes vs Decorative Finishes in the Custom Home Builder Process

Understanding the difference between structural and decorative elements helps you prioritize decisions and manage costs:

Structural Elements (Decide Early)

- Load-bearing wall locations

- Window and door placement

- Mechanical system layouts

- Electrical panel and main service locations

- Plumbing rough-in locations

Decorative Finishes (Can Decide Later)

- Paint colors and wallpaper

- Light fixture styles

- Cabinet hardware

- Flooring materials (in some cases)

- Landscaping details

The Critical Decision Timeline

Structural decisions must be finalized before construction begins. Decorative selections can often be made during construction, but late changes may delay your timeline.

Tech Tools to Visualize & Track Your Selections

Client Portals for Real-Time Updates

Modern custom home builders use dedicated online platforms to keep you fully informed. Think of a tool like BuilderTrend: it’s your central hub.

Through this portal, you can easily view construction progress, access all your important documents (like design selections and financial updates), and communicate directly with your project team. This transparency cuts down on guesswork and keeps everyone aligned, from initial design choices through to the final build.

3D Tours & Virtual Reality

Advanced tools let you “walk through” your home before and after construction. This helps you visualize the space and ensure the final product matches your expectations.

See examples of our home tours.

Mobile App for On-Site Communication

The Buildertrend app enables real-time communication among you, your builder, and subcontractors. Ask questions, approve changes, and see progress photos and schedules right from your phone.

From Permits to Punch List: Tracking Construction Milestones

Once construction begins, staying organized and informed prevents small issues from becoming major problems. The key is understanding what to expect at each milestone.

Your Role on Site: Walk-Throughs, Approvals & Safety

Scheduled Site Visits

We recommend weekly site visits during active construction phases. These should be scheduled in advance and coordinated with your project manager to ensure safety and productivity.

Personal Protective Equipment (PPE)

Construction sites require hard hats, safety glasses, and closed-toe shoes. We provide these during scheduled walk-throughs, but you’re responsible for your own safety gear during unscheduled visits.

Communication Protocol

All questions and concerns should go through your designated project manager. Direct communication with subcontractors can lead to miscommunication and potential liability issues.

Inspections, Permits & Quality Checks You Should Expect

Foundation Inspection

Occurs after footings are poured and before concrete foundation walls. Inspectors verify proper reinforcement, dimensions, and drainage systems.

Framing Inspection

Conducted after wall framing is complete but before insulation installation. This ensures structural integrity and proper installation of windows and doors.

Rough-In Inspections

Separate inspections for electrical, plumbing, and HVAC systems occur after installation but before drywall. These verify code compliance and proper installation.

Energy Code Compliance

Many jurisdictions require energy efficiency inspections to verify insulation levels, air sealing, and HVAC efficiency meet current codes.

Final Inspection and Certificate of Occupancy

The final inspection covers all systems and finishes. Only after passing this inspection can you legally occupy your new home.

Managing Change Orders & Staying on Schedule

Understanding Scope Creep

Small changes can add up quickly. Adding a bathroom, relocating electrical outlets, or upgrading finishes mid-construction often costs 2-3 times more than planning these changes upfront.

Documentation Requirements

All changes must be documented in writing with clear cost and timeline impacts. Verbal agreements lead to disputes and confusion.

Cost Impact Analysis

We provide detailed cost breakdowns for all change orders, including labor, materials, and schedule impacts. This helps you make informed decisions about which changes are worth the investment.

Keeping Your Sanity Through Delays, Warranty & Beyond

Even the best-planned projects face unexpected challenges. The key is preparing for common issues and maintaining perspective throughout the custom home builder process.

Preparing for Inevitables: Weather, Lead Times, Labor Gaps

Building Buffer Days Into Your Timeline

We automatically add 2-3 weeks of buffer time to account for weather delays, inspection scheduling, and minor setbacks. This prevents stress when small delays occur.

Alternative Material Selections

Having backup choices for key materials prevents delays when your first choice becomes unavailable. We maintain relationships with multiple suppliers to ensure continuity.

Escalation Clauses for Labor Shortages

When skilled tradespeople are unavailable, we have agreements with alternative contractors to prevent extended delays. This might involve slightly higher costs but maintains your timeline.

Understanding Post-Construction Warranty & Support

1-2-10 Warranty Coverage Structure

- 1 Year: Workmanship and materials defects

- 2 Years: Major mechanical systems (HVAC, plumbing, electrical)

- 10 Years: Structural components and foundation

Service Request Process

Most warranty items are handled through online portals where you can submit requests, upload photos, and track resolution progress. Response times vary by issue severity.

Annual Maintenance Reminders

Quality builders provide maintenance schedules and reminders to help protect your investment. Following these guidelines ensures your warranty remains valid.

Punch List Management

The final walk-through generates a punch list of minor items requiring attention. These are typically cosmetic issues that don’t affect habitability but should be addressed before closing.

Leveraging Digital Portals for Ongoing Peace of Mind

Progress Photo Documentation

Regular construction photos help you track progress and identify potential issues early. These photos also serve as valuable documentation for warranty claims.

Document Storage and Access

Digital portals store all project documents, including permits, inspection reports, warranty information, and material specifications. This eliminates lost paperwork and provides easy access when needed.

Maintenance Reminder Systems

Advanced portals send automatic reminders for routine maintenance tasks like HVAC filter changes, gutter cleaning, and seasonal inspections.

Frequently Asked Questions about the Custom Home Builder Process

How do I prioritize wants vs needs without busting the budget?

Start by creating three lists: must-haves, nice-to-haves, and dream features. Must-haves are non-negotiable items that affect your daily life or home’s functionality. Nice-to-haves improve comfort or aesthetics but aren’t essential. Dream features are luxury items you can add later if budget allows.

Focus your initial budget on must-haves and select nice-to-haves. You can always upgrade finishes or add features during construction if you’re under budget, but removing planned features to cut costs is more difficult.

What permits and inspections are absolutely mandatory?

Building permits are required for all custom homes and typically include:

- Building permit for structural work

- Electrical permit for all wiring and panel installation

- Plumbing permit for water supply and waste systems

- Mechanical permit for HVAC installation

- Septic permit if not connected to municipal sewer

Inspections occur at specific milestones and must pass before work can continue. Skipping permits or inspections can result in legal issues, insurance problems, and difficulty selling your home later.

How often should I visit the jobsite—and when?

We recommend weekly visits during active construction phases, but timing matters. The best times to visit are:

- Mid-morning (9-11 AM) when trades are actively working

- After major milestones like foundation completion or framing

- Before major decisions like electrical outlet placement or fixture installation

Avoid visiting during concrete pours, roofing work, or when multiple trades are working simultaneously. These activities create safety hazards and limit productive communication.

Conclusion

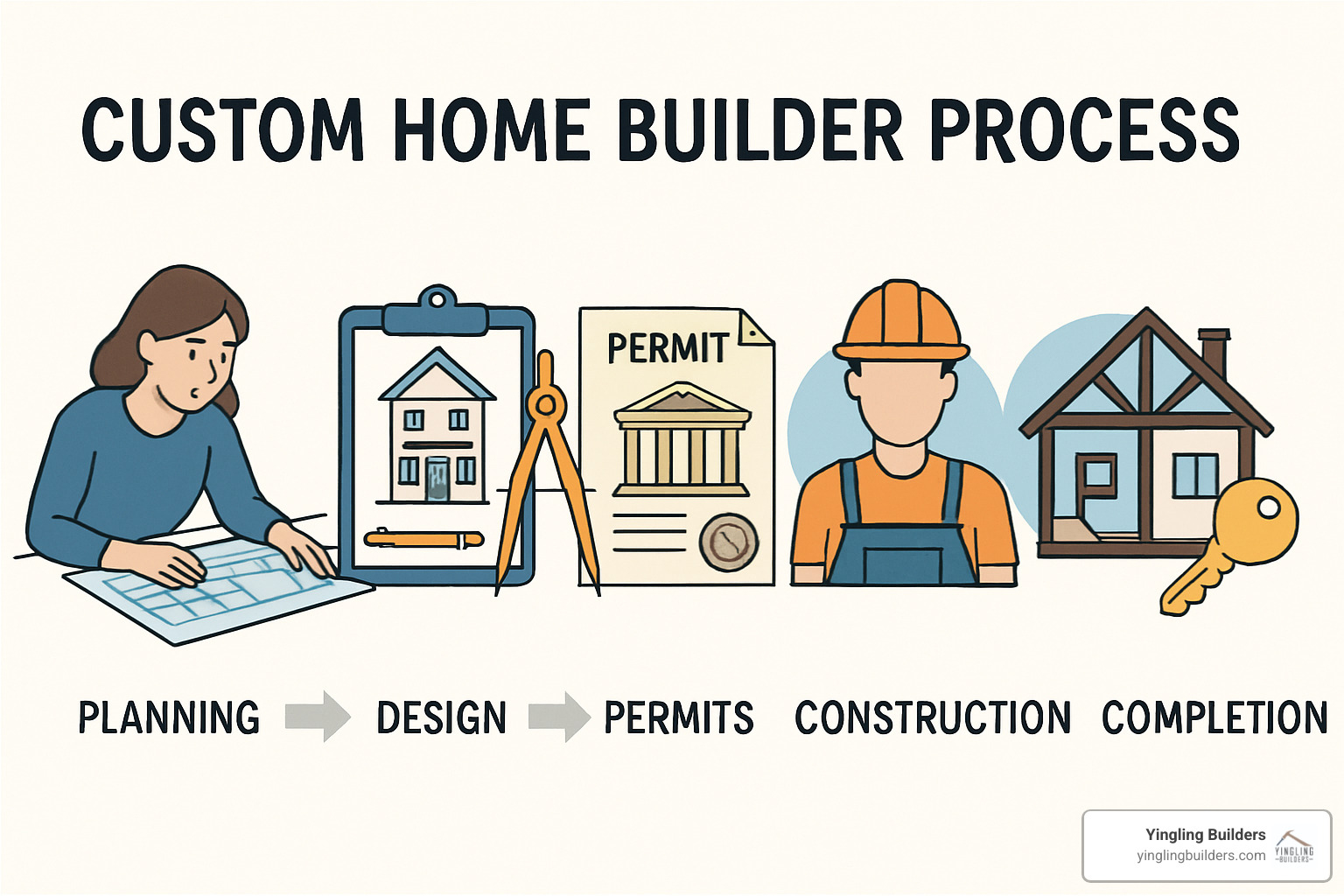

The custom home builder process doesn’t have to be overwhelming when you understand what to expect. By following the six-phase roadmap—planning, design, permits, construction, inspections, and warranty—you can steer each step confidently while avoiding common pitfalls.

Remember these key principles:

- Front-load decisions during planning and design phases

- Maintain realistic timelines with built-in buffers for delays

- Communicate regularly with your builder and project team

- Document everything to prevent misunderstandings

- Prepare for the unexpected with contingency funds and flexible scheduling

At Yingling Builders, we’ve refined our process over 15 years to minimize stress while maximizing quality. Our systematic approach using proven Wausau Homes plans ensures predictable timelines and budgets while still allowing significant customization.

The investment in understanding the custom home builder process upfront pays dividends throughout your project. You’ll make better decisions, avoid costly mistakes, and enjoy the journey of creating your dream home.

Building your custom home in West Central Illinois is a significant journey. We’ve outlined the roadmap, from initial ideas to long-term support, to make it clear and manageable.

Ready to discuss your vision? Let’s connect. Contact us to begin your custom home journey.

0 Comments